Modular Balancing Technology - HAIMER Tool Dynamic

The spindle speed of modern machine tools have increased on a continuous basis in the last few years in order to achieve higher cutting volumes and machine in a profitable manner. The increases have also raised the demands for the tools and holders used, because the higher spindle speeds make the effects of imbalance increasingly more noticeable. The consequences are vibrations, bad surface finish and shorter tool life.

Only the high-precision balancing of tools and tool holders can make the complete capacity of the machines tool with regards to speed, cutting volume and produced surface finish accessible. Because balancing provides for fewer vibrations. It reduces wear of the spindle and tool, reduces the downtimes and increases process security.

Balancing Machines

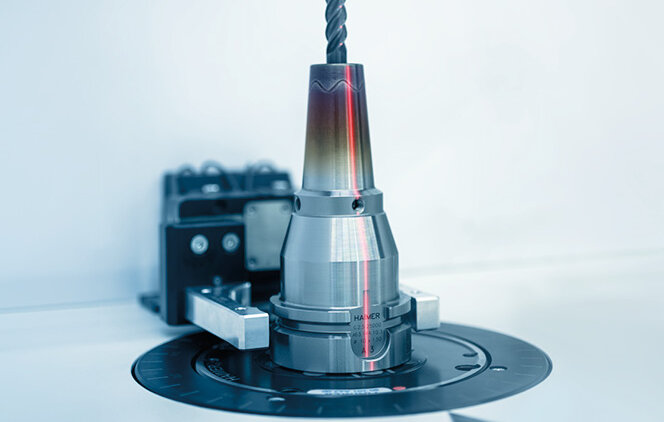

With the Tool Dynamic balancing machine series, HAIMER offers a comprehensive solution for the balancing of tool holders, grinding wheels and big rotors with diameters up to 800 mm. Starting from the table and complementary machine TD 1002 to the automatic balancing machine TD Automatic, HAIMER has the suitable balancing machine for every need.

Accessories for balancing machines

HAIMER balancing machines are set up for maximum flexibility due to their modular concept. In combination with the wide range of high precision balancing adapters for all spindle interfaces, the balancing arbours to balance tools with cylindrical bore as well as the other comprehensive accessories there are no limits set!

SEE MORE

Here you can download the complete product range of the Tool Dynamic Balancing Technology:

Tool Dynamic - Balancing Technology

Modular balancing system