SAFE-LOCK APPLICATION EXAMPLE

AT A LEADING PROVIDER IN THE INDUSTRIAL SEALING TECHNOLOGY

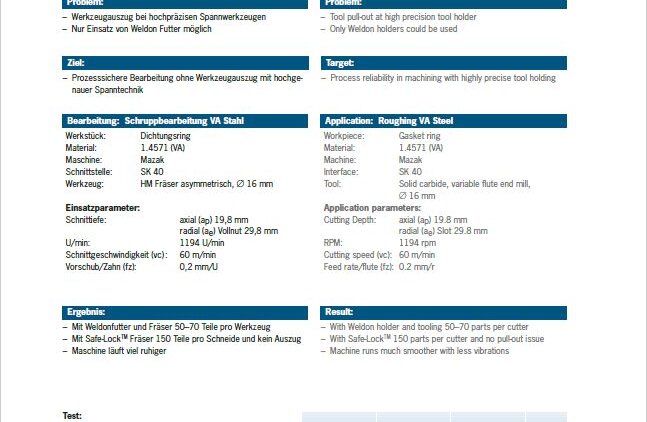

PROBLEM

- Tool pull-out at high precision tool holder

- All tests with different systems failed

- Only Weldon holders could be used

TARGET

- Process reliability in machining with highly precise tool holding

APPLICATION

ROUGHING VA STEEL

| Workpiece: | Gasket ring |

|---|---|

| Material: | 1.4571 (VA) |

| Maschine: | Mazak |

| Interface: | SK 40 |

| Tool: | Solid carbide, variable flute end mill, Ø 16 mm |

APPLICATION PARAMETERS

| Cutting Depth: | axial (ap) 19.8 mm, radial (ae) Slot 16 mm |

|---|---|

| RPM: | 1194 rpm |

| Cutting speed (vc): | 60 m/min |

| Feed rate/flute (fz): | 0.2 mm/r |

Result

- With Weldon holder and tooling 50–70 parts per cutter

- With Safe-Lock 150 parts per cutter and no pull-out issue

- Machine runs much smoother with less vibrations

- In same time 86 pieces higher output i.e. increase by 122%

70 pieces:

Weldon-Aufnahme

Ø 16mm, Length A = 80 mm

156 pieces:

HAIMER Safe-Lock Power Shrink Chuck

40.445.16.37, Length A = 65 mm

APPLICATION EXAMPLE AS PDF DOWNLOAD: