SAFE-LOCK TOOL PULL-OUT PROTECTION

ROUGHING APPLICATION IN THE PACKING MACHINE INDUSTRY

Problem

- Only Weldon holders could be used

- High tool wear on one flute (Tool breakout on the opposite side of the Weldon flat)

TARGET

- Increase of tool life by usage of high precision tool holding instead of Weldon

APPLICATION:

CONTOUR MILLING

| Material: | Steel |

|---|---|

| Cutting tool: | HPC solid carbide cutter with variable flutes Ø = 20 mm, Z=4 |

APPLICATION PARAMETERS:

| Cutting depth: | axial (ap) = 0,75xD; radial (ae) = 10 mm |

|---|---|

| Cutting speed (vc): | 180 m/min |

| Feed rate/flute (fz): | 0,07 mm/U |

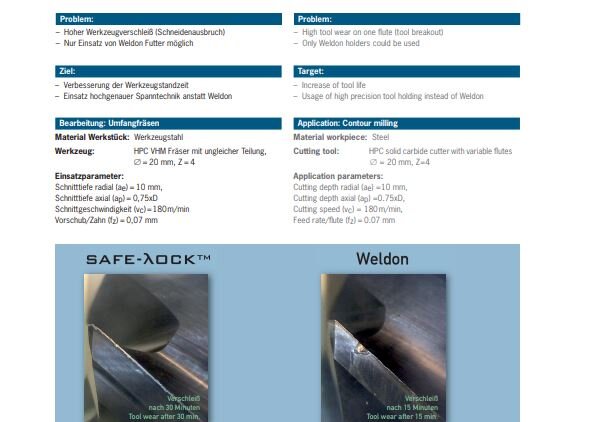

Result

This comparison shows the wear characteristics of the cutting tools at various machining times. Of note is that, in the case of Safe-Lock, even at double the machining time, wear is less prevalent and more´controlled than for Weldon - with 100% protection against pullout.

APPLICATION EXAMPLE AS PDF DOWNLOAD:

Safe-Lock

Roughing application in the packaging machine industry